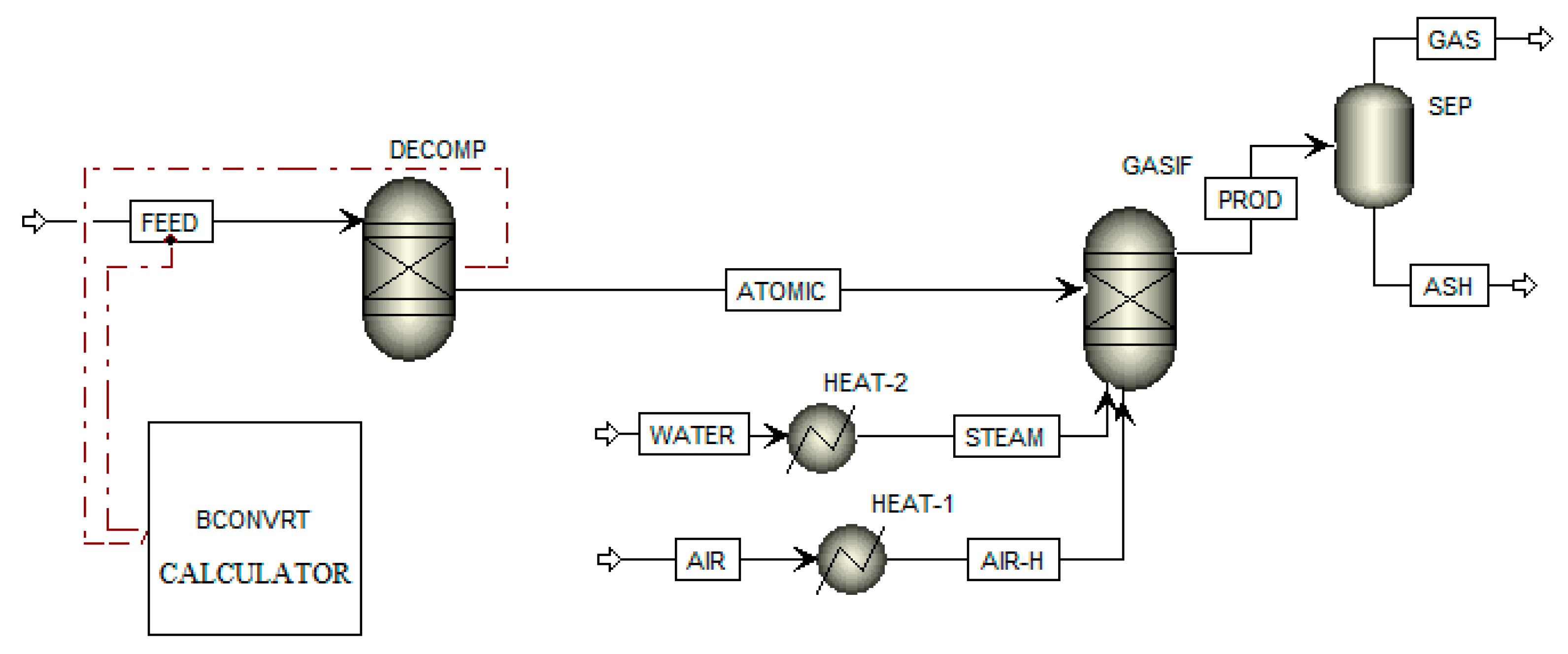

A stoichiometric steady-state model was developed to simulate steam plasma gasification of MSW using ASPEN plus process simulator. Normally undergraduate student projects will involve Aspen Plus or Aspen Properties.

Aspen Plus Modelling Of Air Steam Gasification Of Biomass With Sorbent Enabled Co2 Capture Sciencedirect

The ultimate analysis gives the weight composition of coal in.

. In the pyrolysis process the biomass is devolatilized by heat to char and volatiles. Methanol synthesis simulation 33. To start either of these packages be sure to look.

Gasification simulation model 32. The aim of introducing steam in the coal gasification process was to increase the heating value of the syngas owing to increasing the H 2 and CO contents. In Aspen Plus ultimate analysis results denoted as ULTANAL in Aspen Plus and sulfur analysis results denoted as SULFANAL in Aspen Plus.

The screenshots in this tutorial and some of the menus are outdated. Kennedy12 1 Department of Mechanical Engineering Dublin Institu te of Technology Bolton Street Dublin 1 Ireland 2 Dublin Energy Lab Focas Institute Dublin Institute of Technology Dublin 8 Ireland The efficient utilisation of biomass resources. The proximate analysis gives the weight content of moisture fixed carbon volatile matter and ash.

GUIExamplesEntrained Flow Coal Gasifier folder of the Aspen Plus installation. The effect of SC was studied by using ASPEN Plus and the simulation results were shown in Fig. Hello Im running a simulation on Decomposition and Gasification of Biomass using Aspen Plus.

Getting Started with Aspen Plus or Aspen Properties. Process development simulation. The gasification process of polyethylene PE was successfully modeled using a combination of various unit operation modules available in the Aspen Plus simulation package.

Aspen plus simulation of biomass gasification in a steam blown dual fluidised bed W. Biomass Simulation On Aspen Plus - posted in Chemical Process Simulation. Aspen plus gasification tutorial From time to time youd like an authentic and concurrently a simple nail designThe optimum Remedy may be the designs of your nails with hearts.

Aspen Plus Gasification Tutorial. This textbook chapter provides tutorials for overcoming major challenges such as physical property package selection absorber model convergence. Combustion technology is most widely applied on an industrial scale.

Hi I am trying to simulate biomass gasification using Aspen Plus. Pressure swing adsorption PSA 23. This was done by splitting the gasification process into five different sub processes starting with pyrolysis or decomposition of the feed volatile and non-volatile component separation volatile reactions char gasification and finally solid gas separation.

Completed Mixer Flowsheet Data Input. The gasification temperature is 750 C. Aspen plus modelling 21.

Hi there I am adapting the entrained flow gasifier for coal in the model examples in Aspen Plus to accept plastic as feedstock However I found a warning in my simulation run I did a diagnostic check for mass and molar balance and the message that appears in the control panel reads as follows. Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierapwz a compound file containing these six files. Aspen Plus Simulation of a Coal Gasification Process Geometric Analysis.

O Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierbkp o Aspen_Plus_Model_for_Entrained_Flow_Coal_Gasifierpdf o USRKINf o USRPRESf o. Simulating solvent-based carbon dioxide capture in modern commercial software packages can be very challenging. All of the data input for Aspen is entered in the Data Browser window.

Gasification Aspen Plus reaction kinetic 1 Introduction Biomass is an attractive source of energy. Aspen Plus Gasification Of Coal - posted in Industrial Professionals. I have proximate and.

The modeling of biomass gasification processes by simulators such as Aspen Plus is a powerful tool to assess mass and energy balances and to optimize process designs. A biomass gasification process is presented. Depending on the feedstock.

Since biomass is presented as a Non-conventional component i tried to calculate the yield for the RYield reactor using ultimate analysis results. I found in lot of articles published people use RYield reactor in Aspen plus to simulate the decompostion. A detailed model of the gasification reactor is one of the key points to achieve an accurate process description.

It could be a multicolored scattering of modest drawings or just one heart about the accent on the finger. The model was employed to break down volatile yields released during pyrolysis it was also used to analyze the effect of gasifying agent and plasma gasification behaviour. Process simulation and sensitivity analysis of indirect coal gasification using aspen plus model By Fahim Uddin and Syed Ali Ammar Taqvi Coal gasification by indirect heating in a single moving bed reactor.

ASPEN plus gasification model. Aspen has two features in the Data Browser window that can both help and hurt the user. Methanol synthesis process 3.

However the major steps of working with Aspen are similar to what is depicted below. Biomass gasification using Aspen Plus TABLE OF CONTENTS 1. A biomass gasification process in ASPEN Plus.

It is possible to utilize the energy through the thermo-chemical conversion processes of pyrolysis and gasification. But after running the simulation the feedback. A model for biomass gasification in dual fluidized bed DFB reactors by coupling.

This window can be opened by clicking on the eyeglass icon or by going to DataData Browser in the Menu Bar. Aspen Plus 23 is a comprehensive chemical process modelling system used by both academy and industry for design simulation process improvement and optimizationAspen Plus 23has advanced and dedicated functionalities such as detailed heat exchanger design dynamic simulation batch process modelling. Aspen Tutorial 1 6 Figure 4.

Access Free Simulation Of Coal Gasification Process Using Aspen Plus Coal and Biomass Gasification Biomass can be converted to energy biofuels and bioproducts via thermochemical conversion processes such as combustion pyrolysis and gasification.

Aspen Plus Simulation Of Co Pyrolysis And Gasification Of Plastic And Biomass To Syngas Part 1 Youtube

Aspen Plus Tutorial Nonconventional Feed Simulation Example Coal Drying Simulation Youtube

Aspen Plus Model Flow Sheet For Biomass Pyrolysis Download Scientific Diagram

Energies Free Full Text Thermodynamic Analysis Of Biomass Gasification Using Aspen Plus Comparison Of Stoichiometric And Non Stoichiometric Models

Aspen Plus Model Flow Sheet For Biomass Pyrolysis Download Scientific Diagram

0 comments

Post a Comment